FOR IMMEDIATE RELEASE

Aerospace Materials And Advanced Engineering Used Extensively

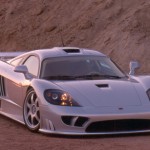

IRVINE, Calif. — The Saleen S7’s 7-liter engine is a technical tour de force, producing 550 horsepower at 6400 rpm. Based on a Ford form factor, the Saleen-massaged all-aluminum V-8 follows traditional American cam-in-block design to produce significant horsepower and torque with high reliability. The engine generates 520 foot-pounds of torque at 4000 rpm, transferred to the rear wheels through a new generation six-speed transaxle.

Although the casting is based on a traditional Ford design, it was completely re-engineered by Saleen to be eight inches shorter than the block on which it was based. This Front Engine Accessory Drive (FEAD) system permits the use of a Saleen-designed, side-mounted water pump to help improve weight distribution and packaging.

Air flows into the engine through a carbon fiber induction system leading to a magnesium throttle body and intake manifolds. Induction is through a true downdraft port fuel injection system directly to the intake ports. Intake trumpets are matched to each cylinder.

The S7 engine uses materials and engineering from aerospace to reduce weight and improve reliability. The all-aluminum Saleen cylinder heads are created using Computerized Numerical Control (CNC) lathes. Beryllium exhaust valve seats allow more efficiency by transferring heat away from the cylinders. Stainless steel valves and titanium retainers are used for durability. Forged pistons reduce reciprocating weight while providing improved strength. Piston rods are made of the latest material, EN40B billet steel. Saleen designed its own crankshaft for the S7, using 4340 forged billet steel.

A Saleen dry sump oil delivery system ensures reduced friction while providing enhanced lubrication to the reciprocating parts. This allows for improved ground clearance and more importantly, in hard or sustained cornering, prevents oil starvation.

Engine placement in the S7 was a consideration as part of the complete engine design process. The mid-engine placement allows the engine to be tall. This design also provides advantageous placement for the induction and exhaust plenums. The camshaft is belt driven to provide more accurate valve placement and reduce noise compared to a chain drive.

The S7’s Saleen-designed muffler is enormous, reducing unwanted noise, and acting as part of the rear impact crumple zone. The exhaust exits through catalytic converters, as the S7 engine is designed to meet all Federal and California emission-control standards as a transitional low-emissions vehicle (TLEV). A Ford EEC V engine management system with direct ignition and OPD II helps the S7 meet the requirements.

The Saleen S7 is certified for sale in both the United States and United Kingdom. Designed and built at Saleen’s Irvine, California manufacturing facility, the S7 is sold in the U.S. through select Saleen Certified Ford dealers and other newly added Saleen Certified dealers specializing in exotic automobiles. Vehicles for Europe and the Middle East will be produced at a satellite facility in conjunction with RML located in England. Worldwide volume is projected to be 300-400 cars over the estimated four-year production run. Work has begun on a less-expensive, higher volume model that will help achieve sales goals.

The Saleen S7 went on sale at its introduction at the famed Monterey Historic Races on August 19, 2000. First vehicles will be delivered to customers in the second quarter of 2001. The Manufacturer’s Suggested Retail Price (MSRP) is $375,000.

The 2001 Saleen S7 is a proof of concept for what Saleen, Inc. has been building for 17 years. As a federally certified specialty vehicle manufacturer, Saleen has produced over 7000 vehicles – using and perfecting the efficient Niche Manufacturing process, which is now being studied and adopted by the world’s major automakers as they strive to quickly and economically bring small volume products to market.

Saleen, Inc. facilities include total research, design, engineering, and manufacturing capabilities. The company’s line also includes the Saleen S281 Mustang, Saleen XP8 Explorer, the SR Widebody, Saleen Performance Parts, and Saleen Engineering and Certification Service.

Contact:

Michael F. Hollander, Pacific Communications Group – 310.224.4981

S7 Release, S7 Chassis, S7 Engine, S7 Body and Design, S7 Features, S7 Manufacturing